The Circular Economy (CE) concept has continuously evolved over the past decades and several authors [1-3] accredit its genesis to Pearce and Turner, who discussed the feasibility of pondering natural resources in economic flows bearing in mind production and consumption loops [4].

One of the main Circular Economy notions used today is described by Ellen MacArthur Foundation as “an industrial economy that is restorative or regenerative by intention and design” [5]. Webster supplemented that “a circular economy aims to keep products, components and materials at their highest utility and value, at all times” [6]. The concept was furthered by Bocken et al. as “the design and business model strategies slowing, closing, and narrowing resource loops” [7]. It was pointed out by Yuan that CE is “the use of raw materials and energy through multiple phases in a closed flow” [8], incorporating the energy efficiency component to the concept

Considering all these different concept nuances, the circular economy could be broadly described a ‘regenerative system in which resource input and waste and their consequent emissions and energy use are curtailed by closing, slowing down, or narrowing typical materials loops through processes like design, repair, reuse, recycling, among others’ [9].

There are several benefits in fostering CE as an effective system to boost the conversion of waste into new valuable resources and lessen waste creation, some of which highlighted as follows:

- Resource preservation: better control of natural capital and finite stocks by offsetting the flow of renewable resources.

- Increase of collaboration and technology advancements: promotion of design thinking and co-creation strategies, enabling new technologies to efficiently use natural capital and optimize product life cycles.

- Reduced environmental impact: enhance resource yields by circulating products, components, and materials in use at the highest possible levels at all times.

- Economic growth: an increase in productivity and cost savings. According to the report ‘Growth within: A Circular Economy Vision for a Competitive Europe’ CE cost-saving figures alone would represent at least 600 billion Euros per year by 2030 [10].

- Systemic changes: integrate key stakeholders of the value chain to ensure infrastructure modifications required to eliminate externalities and scale-up solutions.

- New business opportunities: the interconnected nature of the circular economy generates new business models and reveals novel interaction routes among the value chain players that can be translated into sustainable businesses.

- Job creation: new job opportunities will arise with a new CE approach and around 600,000 jobs could be generated in Europe alone should the CE implementation be effective [11].

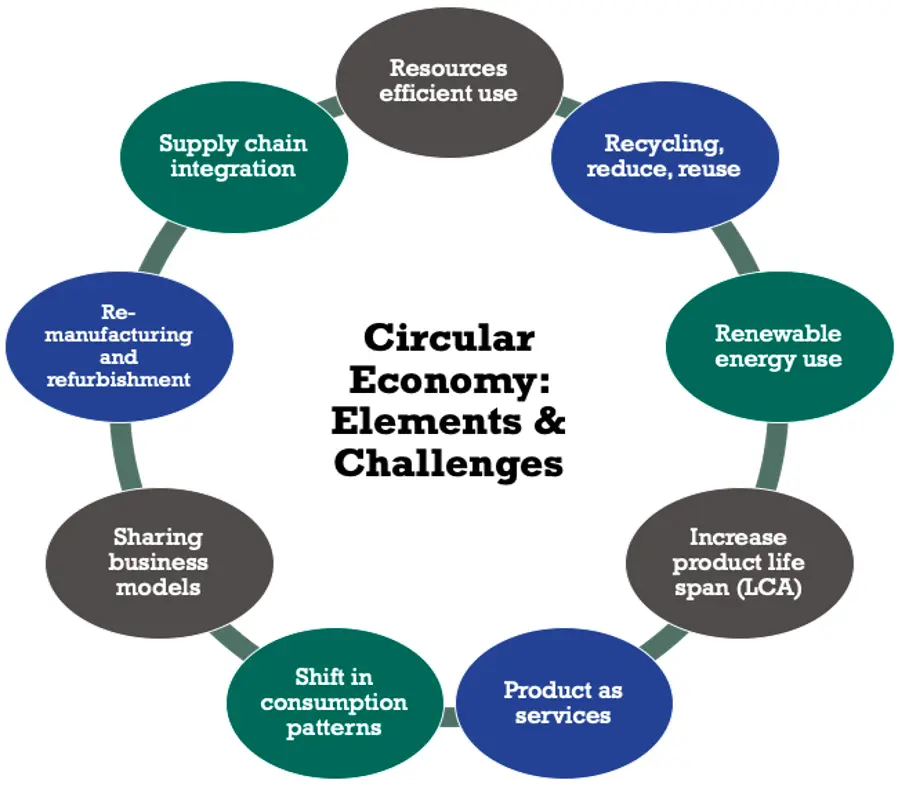

Despite the several advantages brought a CE approach, there still are several challenges to be overcome so it is successful. The following diagram shows some of the key elements and challenges faced to implement CE.

These different elements may affect each industry in distinct proportions. A key criticism starts with the different concept definitions, which could delay international cooperation and generate a misalignment in assessing the real impact of the transition from linear to circular.

Another point of concern is the fragmented approach in each region, with no international policy framework that integrates circular-economy tactics. The lack of these policies hinders the process to achieve the UN Sustainable Development Goals (SDGs).

Additionally, little is known about the current economic scenario of companies already operating in a more circular fashion. For example, CE sceptics claim that European companies are already capturing most of the economically viable opportunities especially related to recycling, and that would imply that a higher level of circularity could increase costs in the long run [12]. The real magnitude of net environmental impacts is also questioned by them, as some initiatives could be hard to gauge due to their intra-connected nature with a broader systemic network across the value chain.

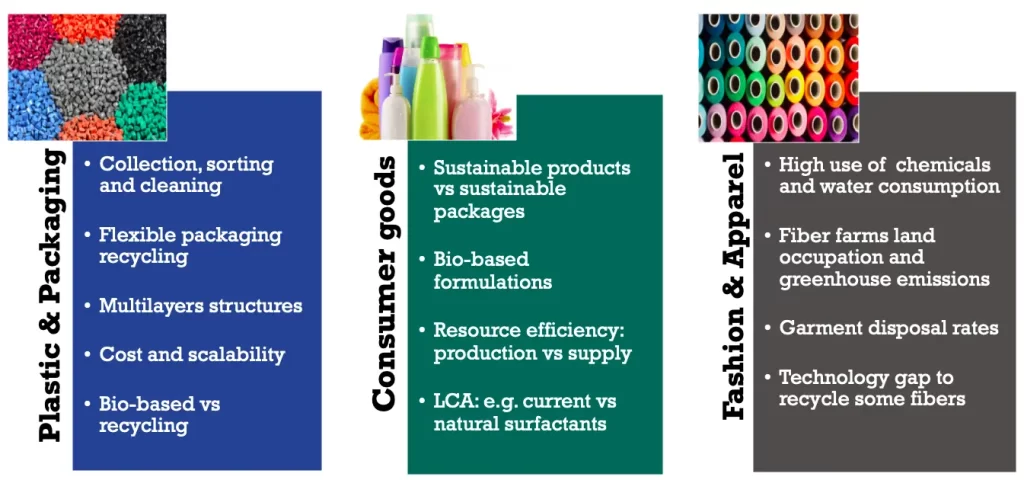

On top of these contextual challenges, there are also some industry-specific dilemmas that companies face to promote and scale CE initiates. Here are a few examples:

CE aspects and examples across varied industries:

- Plastic & Packaging: The are several challenges faced within the plastic industry to implement CE. Collection, sorting and cleaning of waste are very diverse in the different regions, which hampers scalability and quality of waste available for recycling. The presence of several hard-to-recycle flexible packages and multi-layer structures also hinders the efficiency of CE. The investment costs in infrastructure and scalability of more well-rounded solutions such as chemical recycling also pose a challenge for effect CE implementation in this industry. Finally, misalignment to assess bio-based and recycling options are also escalated by the lack of industrial coalition and public policy agreements.

- Consumer Goods: Among the several challenges faced by the consumer goods industry to promote Circular Economy, there is a paradox of offering well-rounded sustainable solutions. It is often seen that some products have a sustainable formulation but in a non-sustainable package and vice-versa. Closing this gap between product and package offering is a huge challenge but also presents companies with a real opportunity to differentiate themselves in the marketplace. Another dilemma is related to balancing out the % of bio-based formulations to ensure that life cycle assessments are efficient, and the truly sustainable options are chosen not only based on the “bio” claim but for their true net environmental impact. This includes also the appraisal of resource efficiency (water, energy, shipping, etc.) during production and supply of packaged goods.

- Fashion & Apparel: The fashion and apparel industry presents some particular challenges such as the use of chemicals and high-water consumption for the mass production of clothes. Another factor that hampers a systemic CE implementation in this sector is related to the amount of land required to produce fibres and their subsequent high level of greenhouse emissions. Now, the biggest problem to close loops in this chain is related to the high rate of garment disposal, associated with consumer behaviour, and the inefficiency of current technologies to reliability turn some type of fibres into new clothes. So, the opportunity relies on the use of more environmentally friendly chemicals, optimization of cotton farming, reduction of resource use, and improvement of recycling technologies.

Despite the different challenges and concerns in each industry, the Supply Chain system is identified as a common thread that could be the initial answer to minimize issues and advance Circular Economy across industries. Especially for consumer-related products, supply chain activities are responsible, on average, for nearly 80% greenhouse emissions and over 90% of its impact on air, land, water, and biodiversity [12]. Similar high impact numbers are observed also for other sectors like plastic, fashion, food and beverage, chemicals, paper, etc. Thus, operations optimization can be a powerful tool to further CE concepts across different industries.

The interpretation of the circular economy still follows a wide breadth of concepts that, though have similarities, may vary by industrial sectors and policy levels. Despite those differences, especially related to materials and resources utilization, a clear trend for a systemic transformation is seen across industries with some similar opportunities such as the improvement in operations especially the efficiency of the supply chains.

There is still a huge challenge ahead, but slowly a shift in the management approach is seen towards integrating sustainability as a business driver to enable effective implementation of the circular economy.

So… what are they key Circular Economy challenges faced in your industry?

References:

[1] Andersen, M.S., “An introductory note on the environmental economics of the circular economy.” Sustain. Sci. 2 (2007).

[2] Su, B., Heshmati, A., Geng, Y., Yu, X., “A review of the circular economy in China: moving from rhetoric to implementation” J. Clean. Prod. 42 (2013).

[3] Ghisellini, P., Cialani, C., Ulgiati, S., “A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems” J. Clean. Prod. 114 (2016).

[4] Pearce, D.W. and Turner, R. K., ”Economics of Natural Resources and the Environment” Johns Hopkins University Press (1989).

[5] Ellen MacArthur Foundation (EMF), “Towards the Circular Economy”, vol.1. Isle of Wight (2013).

[6] Webster, K., “The Circular Economy: A Wealth of Flows”, Ellen MacArthur Foundation, Isle of Wight (2015).

[7] Bocken, N.M.P., de Pauw, I., Bakker, C., van der Grinten, B., “Product design and business model strategies for a circular economy” J. Ind. Prod. Eng. 33 (2016).

[8] Yuan, Z., Bi, J., Moriguichi, Y., “The Circular Economy: A New Development Strategy in China” J. Ind. Ecol. 10 (2008).

[9] Geissdoerfer, Martin; et. al. “The Circular Economy – a new sustainability paradigm” Journal of Cleaner Production. Vol. 143 (2017).

[10] Ellen MacArthur Foundation (EMF) “Report – Growth within: A Circular Economy Vision for a Competitive Europe” (2015).

[11] Marino Cavallo and Daniele Cencioni “Circular Economy, benefits and good practices” CESME, European Regional Development Fund, Edizioni Ambiente (2017).

[12] McKinsey report “Mapping the benefits of a circular economy”, McKinsey & Company Quarterly report (2017).